Spurred by recent federal legislation, the industrial sector is investing in developing low-carbon technologies to use in its facilities. But wide deployment of these innovative tools and processes is challenging and will not happen by itself. To accelerate their use, Congress should continue to fund research into implementing promising manufacturing technologies rapidly and cost-effectively.

The Infrastructure Investment and Jobs Act, the Inflation Reduction Act (IRA), and the CHIPS and Science Act are expanding domestic investments in new manufacturing. To meet demand, companies across the country are committing over $500 billion to build factories and strengthen their supply chains, with more investments on the way. Scaling the use of innovative low-carbon manufacturing processes that have been proven in labs and in pilots will be essential to achieving industrial decarbonization. Federal lawmakers can boost U.S. industry while helping meet federal climate goals by supporting research that will enable large-scale integration of these key manufacturing technologies into industrial facilities and value chains.

Research enables companies to increase adoption of new technologies

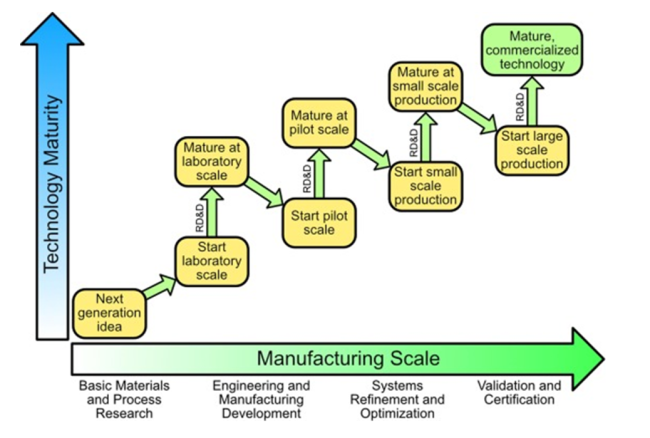

As figure 1 illustrates, technologies go through several stages on the path to large-scale production, and each increase in production requires a corresponding advance in manufacturing know-how. For this reason, research is critical not only in the early stages (to develop new industrial technologies) but also in the later stages of implementing the technology and setting it up for commercial success. U.S. national labs, universities, and private industry are developing these innovative low-carbon technology solutions, but production processes that work in a smaller, more controlled environment don’t necessarily map onto what is required for success at a larger scale. Companies may need to adjust machinery and process controls to adapt to larger volumes or identify new, reliable sources of production inputs. For example, in the food and beverage sector, facilities using industrial heat pumps to electrify their process heat might need to alter their plant layouts to accommodate additional production lines as they scale. This expansion could then require reengineering the heat sources, sinks, and couplings of their heat pumps to meet production and efficiency requirements.

Implementing these technologies on the factory floor doesn’t typically happen through one defining breakthrough but rather through incremental steps and minor innovations. Research that investigates the nuts and bolts of scaling up will help ensure that cleaner manufacturing technologies can become commercially successful and integrated within U.S. manufacturing value chains, from raw material sourcing, to production, consumption, and eventual disposal or recycling.

Figure 1. Visualization of the steps required to scale a new technology from initial lab trials to production embedded in the value chain. With each advance in manufacturing scale, there needs to be a corresponding investment in research. Image via Rissman et al.

Federal research support can accelerate the path to commercial viability

Congress should encourage the Department of Energy (DOE) to expand its research vision to include the challenges of scaling up later-stage technologies. DOE is experienced at transitioning lab-scale technologies to pilots and is well positioned to help later-stage technologies, as it did 25 years ago with the Industries of the Future program. DOE can protect proprietary market information while building a roadmap for companies to efficiently adopt low-carbon technologies in their operations and value chains. This support will help reduce project risk for companies implementing these innovative technologies, as reaching commercial scale is significantly more capital-intensive than lab-scale development. The government’s reluctance to support commercialization research has meant fewer field trials for manufacturers, limiting their ability to validate production technologies through case studies.

While the IRA and other federal legislation propelled demand for low-carbon products and will support capital-intensive projects, building national expertise in scaling and integrating low-carbon manufacturing technologies in the value chain will stretch taxpayer dollars further, move the market faster, and maximize the benefits and opportunities of the current manufacturing expansion. The next decade will be essential to decarbonizing the industrial sector and combating climate change, and federal support to help researchers and industrial companies advance low-carbon manufacturing technologies is critical.