Industrial electrification will be a critical part of the clean energy transition, especially the decarbonization of industrial process heat and other large-scale heating needs. ACEEE, Climate Imperative, and the Consulate General of Denmark in Silicon Valley are hosting a study trip to Denmark to help inform key stakeholders about industrial decarbonization opportunities.

This page includes seven sections (each bullet is a link):

- Review of Industrial Heat Pumps

- Review of Electrified Industrial Heat

- Electrification and Industry in the United States

- Electrification and Industry in Denmark

- Resources to learn more

Review of Industrial Heat Pumps

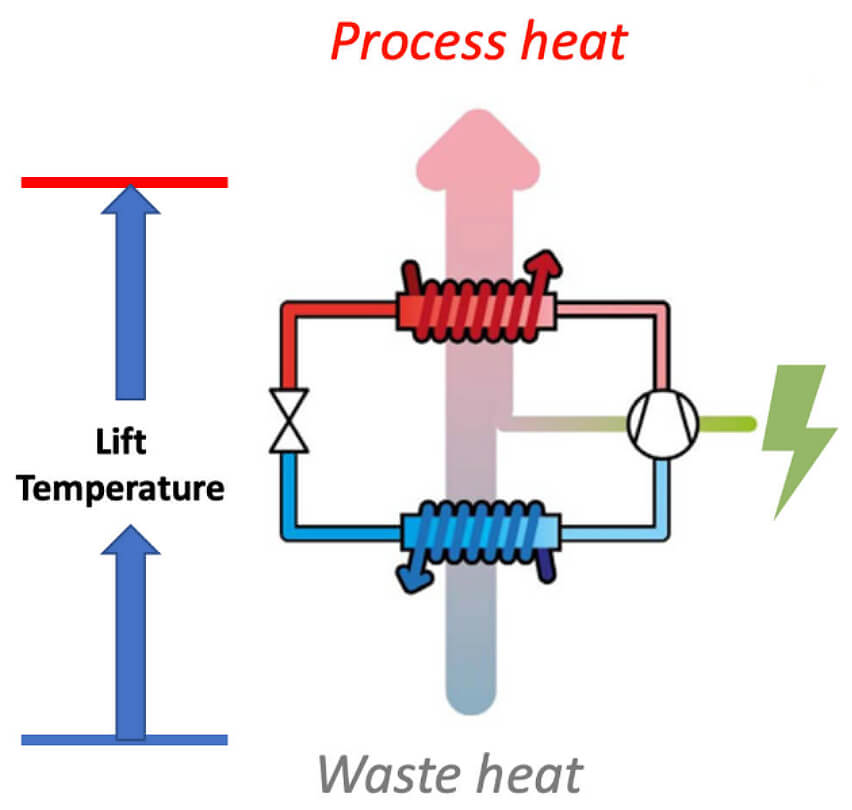

Industrial heat pumps (IHP) are one of the most important electric technologies for low- to medium-temperature process heat applications (up to 160°C, 320°F). While residential heat pumps typically move thermal energy from ambient air into hot air or hot water, industrial-scale heat pumps are more efficient when they move energy from wasted heat (such as glycol emerging from a cooling loop or hot water after being used for sanitation).

Industrial heat pumps (IHP) are one of the most important electric technologies for low- to medium-temperature process heat applications (up to 160°C, 320°F). While residential heat pumps typically move thermal energy from ambient air into hot air or hot water, industrial-scale heat pumps are more efficient when they move energy from wasted heat (such as glycol emerging from a cooling loop or hot water after being used for sanitation).

IHPs are primarily being contemplated for heating, not cooling, since industrial sites already have very efficient electrified cooling options.

IHPs operate on basic refrigeration principles, expanding or compressing refrigerants instead of generating heat through the combustion of fossil fuels. IHPs are driven by external energy, either electrically, mechanically, or thermally. The most common IHP is an electric motor-driven heat pump. For additional information, please watch the videos on electrification and IHP basics from Jeff Rissman and Andrew Hoffmeister.

To date, the uses of IHPs in U.S. industry have been limited to niche applications with little visibility. Traditional barriers have included low natural gas prices, limited product availability, and limited workforce and engineering experience. But IHPs’ potential to energize domestic industrial decarbonization is staggering. ACEEE research shows that IHPs can reduce the following:

- Up to 32% of the energy use associated with industrial process heat

- 30–43 million metric tons of carbon dioxide emissions per year by 2050, equivalent to the emissions from 6.5–9.2 million gasoline-powered passenger vehicles driven for one year

These reductions can be deepened even further with a greening grid, efficient use of thermal energy, associated co-benefits, and the potential use of other technologies, such as thermal storage.

Review of Electrified Industrial Heat

IHPs are not the only technology option available for electrifying industrial process heat. There are applications and temperature needs for which IHPs are not a fit. Additionally, trim heat and reliability concerns often require systems that include multiple technologies.

Options for Direct Electrification of Industrial Heat. Source: Rissman 2024.

Low temperature | -Industrial heat pumps -Waste heat recovery |

Medium temperature | -Electric resistance (also for some high temp.) -Infrared heating -Dielectric heating |

High temperature | -Electric arc (arc furnaces, arc welding, plasma cutting, plasma torches) -Lasers, electron beams (for precision applications) |

Range of temperatures | -Electric boilers -Thermal energy storage -Induction |

To highlight a few technologies:

- Electric boilers run on electricity and can achieve efficiencies of around 90%. They are drop-in replacements for fossil fuel–fired boilers to generate hot water or steam.

- Thermal storage (thermal or heat batteries) uses different materials to store heat that can later be used for industrial processes. Thermal storage can be used for lower-temperature processes in conjunction with IHPs. Higher-temperature storage (e.g., for heavy industry) is reaching the early stages of commercialization.

- Induction heating operates through the heating of conductive material via varying magnetic fields and can reach temperatures between 100°C and 3,000°C. This technology is typically used in primary metal manufacturing.

For more information, please refer to Jeff Rissman’s Zero-Carbon Industry book chapter 6 and the Renewable Thermal Collaborative’s Electrification Action Plan (see resources section below).

Electrification and Industry in the United States

Industry accounts for more than 30% of domestic energy use and energy-related carbon dioxide (CO2) emissions. Industrial energy use and emissions are driven by

- chemical manufacturing (20%),

- refining (17%),

- iron and steel (7%), and

- food and beverage (6%).

Along with paper manufacturing, these sectors account for 674 of the 771 million metric tons CO2e emitted in the generation and use of industrial process heat. Therefore, electrifying this industrial process heat is a crucial decarbonization driver.

Currently, industry gets only 17.6% of total site energy and less than 5% of total process heat energy from electricity. For additional information on industrial emissions and breakdowns by state, visit the resources below from Industrious Labs.

In 2023, the U.S. Department of Energy launched the Industrial Heat Shot, which aims to develop cost-competitive industrial heat decarbonization technologies with at least 85% lower greenhouse gas emissions by 2035. This effort was created to support larger industrial decarbonization goals in the Decarbonization Roadmap, which roughly means eliminating 575 million metric tons of CO2e by 2050. But how do we reach either of those targets?

IHPs will be a large part of industrial electrification. They are often the most economical and efficient alternative to fossil fuel–fired ovens and boilers. Significant public and private investment will be needed to facilitate the market transformation and deployment effort required to offset and replace entrenched and incumbent fossil fuel systems.

Existing and upcoming efforts and examples include:

| Federal Programs: | State Programs: | Utility Programs: |

To support domestic IHP manufacturing:

| To include IHPs and beneficial electrification in climate action plans and clean heat standards:

| To identify opportunities:

|

To identify opportunities and provide technical assistance:

| To identify opportunities:

| To demonstrate potential:

|

To provide financial assistance for implementation:

| To provide financial assistance for implementation:

| To provide financial assistance for implementation:

|

These programs and policies can be expanded to reach new end-users and enable them to access all the savings IHPs can enable.

Electrification and Industry in Denmark

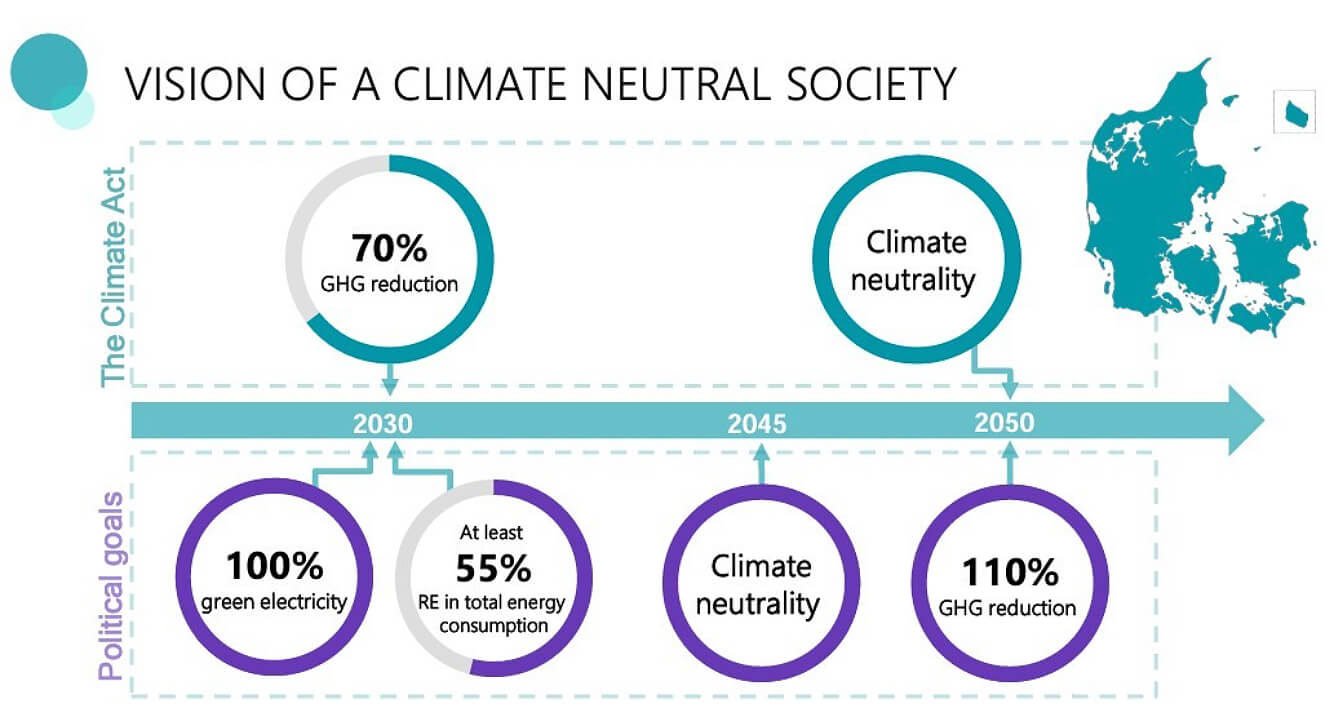

Denmark has an established vision for a climate-neutral society by 2050. This includes a 70% reduction in greenhouse gas emissions by 2030. A combination of public policy measures has helped shape this transition and guide Danish industry toward the reductions needed to accommodate these ambitious targets.

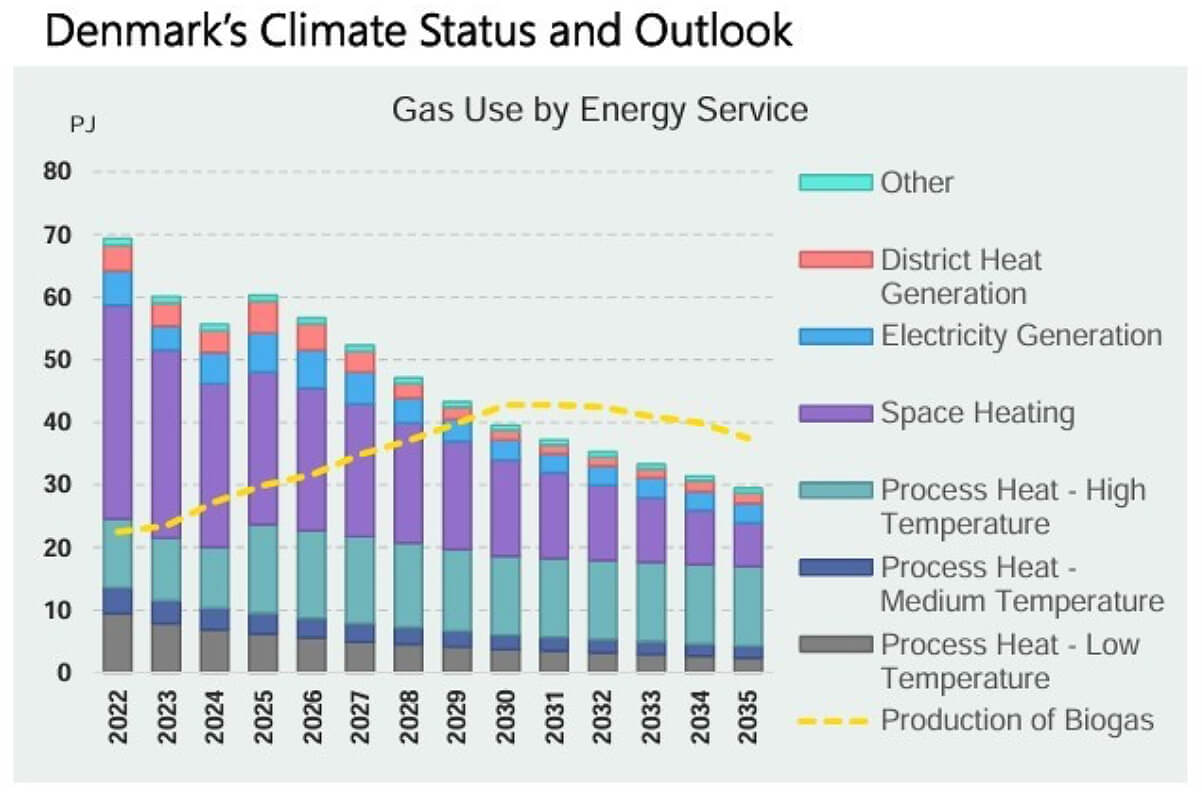

Danish policy that has enabled electrification and the decline of natural gas use (depicted in the graphic below) includes:

Economic measures:

- CO2 tax (introduced in 1993);

- CO2 price for heavy industry;

- Support schemes for energy efficiency and district heating.

Information and knowledge gap measures:

Information and knowledge gap measures:

- Energy management;

- Mandatory energy audits.

Regulatory measures:

- No limits on energy efficiency in industry

- Particulate emission limits (NOx, SOx, CH4)

- Denmark's support schemes for energy efficiency and decarbonization enabled over 560 projects by 2022. 50% of those projects included electrification, while 30% included heat pumps.

The International Energy Agency’s (IEA) high-temperature heat pump annexes include Danish heat pump case studies. Annex 48 has 22 installed IHP cases totaling 19 MW in capacity. Applications of IHPs included drying air for milk powder, cooling water for a university hospital, industrial washing, cooling water supply to a factory, and others. A link to these is included in the resources below.

Resources to learn more

Please consult the following list of resources and the linked pages in the text above for more information. Please feel free to contact us with questions or requests for more context using the emails at the bottom of this page.

General Information:

ACEEE Industrial Heat Pump Landing Page

ACEEE Industrial Electrification Brief: How to Decarbonize Industrial Process Heat While Building American Manufacturing Competitiveness

Lawrence Berkeley Lab Report: Electrification of U.S. Manufacturing With Industrial Heat Pumps.

Renewable Thermal Collaborative Industrial Heat Pump Decision Tool

Renewable Thermal Collaborative Electrification Action Plan

Electrify This Podcast, Clean Industry Needs Electrification

Electrify This Podcast, A Roadmap for the Zero Carbon Industrial Transition

Energy Innovation's Decarbonizing Low-Temperature Industrial Heat in the U.S

Decarbonizing the Industrial Sector, Jeffrey Rissman, Stanford Energy Seminar

Zero-Carbon Industry: Transformative Technologies and Policies to Achieve Sustainable Prosperity (Center on Global Energy Policy Series), book by Jeffrey Rissman

Industrious Labs: U.S. Industrial Facilities Emissions

Industrious Labs: Industrial Heat Dashboard

South Coast Air Quality Management District Proposed Amended Rule 1146.2, Control of Oxides of Nitrogen (NOx) from Large Water Heaters, Small Boilers and Process Heaters

ACEEE Topic Brief on IHP Co-benefits, The Industrial Heat Pump Opportunity Goes Beyond Energy Savings

Danish and EU Resources:

European Heat Pump Association's EU Heat Pump Accelerator

Presentation from Claus Krog Ekman at UC Davis Industrial Decarbonization Symposium

IEA's HTHP Annexes

Fraunhofer ISI, DENEFF, Energy Innovation study on Direct Electrification of Industrial Process Heat

Additional Articles:

ESG Dive Article, Lego Links Employee Compensation to Decarbonization Goals

Office of Clean Energy Demonstrations Project Funding, Industrial Demonstrations Program Selections for Award Negotiations: Heat

Defense Production Act Heat Pump Program Selections

PR Newswire Article, South Coast Air Quality Management District Approves Rule to Accelerate the Transition to Zero-Emission for Building Water Heaters.

Presentations from the trip:

DTI - Decarbonizing Industrial Process Heating

DTI - Electrification Includes Batteries

EnergiNet - Green Transition, the Danish Experience

EnergiNet - Tarriffs, Connection, and Markets

EnergiNet - Welcome to EnergiNet

Johnson Controls - Overview, Policy, Case Studies

Please contact Nanna Duedahl Nørgaard (nannor@um.dk) with specific trip-related queries.

Please contact Andrew Hoffmeister (ahoffmeister@aceee.org) with questions about IHPs and ACEEE's work.