Proposed heavy-duty vehicle emissions standards fail to encourage improvements in non-electric models. The final standards should take advantage of cost-effective fuel-saving technologies to further reduce emissions.

The EPA is expected to finalize new rules for heavy-duty vehicles (HDVs) in the coming weeks. The agency’s proposal falls short by missing the opportunity to save fuel and reduce emissions in internal combustion engine vehicles (ICEVs) by spurring wider adoption of technologies that are already or could become available in the time frame of the standards. The proposal also inadequately pushes zero-emissions vehicles (ZEVs).

Forgoing a push for increased ICEV efficiency improvements beyond levels required by the current standard would have a significant cost. For sleeper cab tractors alone, spurring ICEV efficiency improvements between 2028 and 2032—the years at issue in these “Phase 3” standards—can cut 154 million metric tons of CO2 emissions, according to an ACEEE analysis. Improving HDV efficiency past earlier Phase 2 standards for Phase 3 model years and pushing for more electrification can together lead to health and climate benefits worth billions, with much of them occurring in environmental justice communities.

Cost-effective options to improve efficiency exist

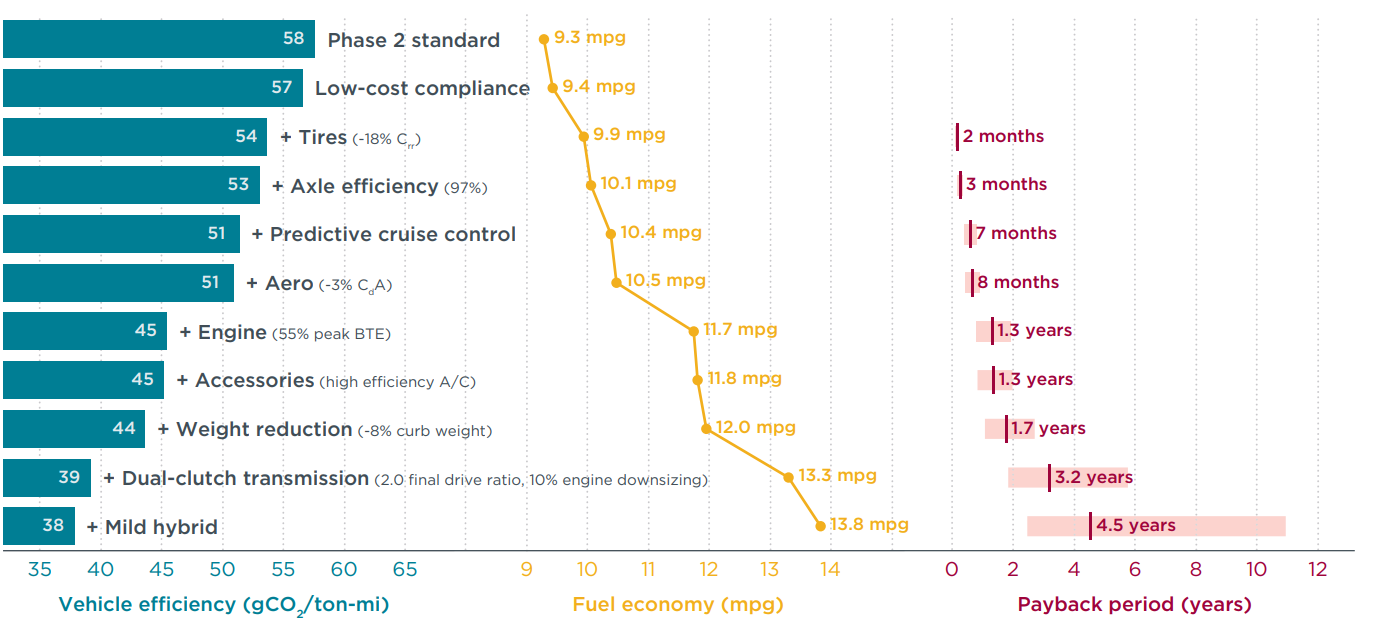

With more than two-thirds of HDVs sold during Phase 3 model years projected to be ICEVs under the proposed standards, allowing the efficiency of these vehicles to stagnate would contravene EPA’s goal of maximizing emissions reductions. A 2023 International Council on Clean Transportation (ICCT) analysis models several potential cost-effective, fuel-efficient technologies that can vastly reduce greenhouse gas (GHG) emissions after 2027. Technologies that paid for themselves in approximately two years through fuel savings included weight reduction, aerodynamic improvements, reduced tire rolling resistance, and engine improvements (peak brake thermal efficiency). ICCT’s analysis found a post-2027 total efficiency improvement potential of 10–31% for tractor trucks and vocational vehicles (depending on vehicle type) over 2027 emissions targets. The figure below shows the incremental technological improvements, their resulting efficiency gains, and payback periods for class 8 high roof sleeper cab tractor-trailers.

Technology improvements for Class 8 sleeper cabs (Source: ICCT, 2021)

The benefits of improved aerodynamics, mass reduction, and reduced tire rolling resistance could also extend to ZEVs, resulting in range extensions and making them a crosscutting investment. The EPA acknowledged in its proposed rule and regulatory impact analysis that further emissions reductions are possible for ICEVs through advancements beyond current market technologies. However, it failed to consider in its analysis standards levels that would help spur such advances.

Ignoring progress on ICEVs could even weaken electric truck expansion

While the proposed rule uses ZEVs as a compliance pathway, the standards are technology-neutral, meaning manufacturers can choose from several possible technology pathways to achieve GHG reductions. Excluding ICEV improvements from the modeling used to inform the proposed Phase 3 standards means manufacturers can work toward achieving these standards by improving ICEV efficiency on their own. This may result in fewer ZEVs as the unaccounted-for ICEV efficiency improvements likely to occur in 2027–2032 still count toward rule compliance. For example, by achieving ICEV improvements for sleeper cabs, manufacturers could comply with the standards without selling any sleeper cab ZEVs, even though EPA’s proposal suggested it would spur a modest 25% electric adoption rate for these types of trucks in 2032. Solutions described in the ICCT analysis (above) and advancements through the Department of Energy’s (DOE) SuperTruck program (detailed below) are prime examples of technologies that support and justify the feasibility for the EPA to set more-stringent rules.

Demonstrated and emerging SuperTruck technologies can support more-stringent standards

The DOE’s SuperTruck is a federally funded innovation program for HDV manufacturers and suppliers of class 8 heavy-duty trucks with the goal of improving truck efficiency. According to NACFE’s latest report, the fuel economy improvements seen through SuperTruck II confirm the potential for further “significant efficiency gains” for heavy-duty trucks. Through SuperTruck II, truck manufacturers Volvo, Peterbilt, and Navistar reported total freight efficiency improvements of 134%, 132%, and 170%, respectively (including trailers) relative to each manufacturer’s 2009 baseline truck. Volvo’s latest 2024 VNL model already applies several lessons that were learned from its SuperTruck II concept truck, boasting a 10% fuel efficiency gain.

Manufacturers reported efficiency gains through aerodynamics, light-weighting, tire rolling resistance, mild hybridization, and other engine improvements. The ICCT has also identified some of these technologies as having the potential to contribute vehicle efficiency gains and emissions reduction for vehicles manufactured post-2027, as mentioned above. The EPA should also consider advancements in ICEV efficiency through SuperTruck innovations and their commercialization potential in its analysis for developing the final standards. Given that the benefits of increased efficiency could also extend to electric trucks, companies investing in both ICEVs and ZEVs stand to save money.

EPA should seize the opportunity of existing and new technologies

The potential of cost-effective and emerging technologies shows that improving ICEV efficiency can accelerate emissions reductions. The final rule should thus be set at levels that both push ZEVs and help spur the adoption of efficiency improvements in ICEV trucks.