We found 174 counties where industrial boilers contribute to unsafe air quality. Local air regulators and states can achieve cleaner air by adopting policies to accelerate installation of electrified technologies.

Industrial boilers, which burn fossil fuels to provide steam or hot water for manufacturing processes, emit significant amounts of air pollutants. Despite the availability of cleaner technologies, these boilers remain in use in many communities that experience poor air quality, endangering residents’ health.

We mapped where small industrial boilers are found across the United States in areas that exceed legal limits (known as nonattainment) for ozone, a type of air pollutant that can cause adverse health and environmental impacts such as respiratory issues in humans and reduced crop productivity. While boilers do not produce ozone directly, they emit nitrogen oxides that contribute to ozone formation. We focus on smaller boilers because their contribution to emissions is often overlooked by reporting requirements, yet their pollution is the easiest to address today through electrification. We identified 174 counties with such boilers operating in ozone nonattainment areas, pointing to the opportunities to reduce this pollution.

Industrial heat pumps available today can replace small boilers

Like a residential refrigerator or heat pump, an industrial heat pump (IHP) moves heat via a working fluid (refrigerant) that changes phase and pressure in a continuous cycle. Powered by electricity, IHPs do not directly emit health-harming pollutants, and they offer a pathway to eliminate boiler emissions. While electric boilers provide another route, IHPs are far more efficient, typically generating three times more process heat than the energy required to drive them, because they move heat rather than generating it from scratch. IHP technology is continually developing, with many manufacturers offering heat pumps with larger and larger capacities.

Not only do IHPs benefit neighboring communities' air quality, but they also offer other benefits to industrial facilities, their workforce, and potentially the local economy. Industry is always looking for greater efficiency to reduce costs and improve productivity.

Where are the easiest opportunities to alleviate industrial air pollution?

Using Schoeneberger et al.’s boiler inventory (which we have found to be the most comprehensive and recent inventory), we located boilers with capacities less than or equal to 50 million British thermal units per hour (MMBtu/hr) in counties within nonattainment areas, as defined by the Environmental Protection Agency (EPA) 8-hour ozone standards set in 2015. These industrial boilers could be most easily replaced with IHPs available today. (Note that IHP capacities are sized in megawatts (MW); a 50 MMBtu/hr boiler can be replaced with a 15 MW IHP).

The counties of interest with the most ≤50 MMBtu/hr industrial boilers are:

- Cook County, IL (297 boilers)

- Philadelphia County, PA (127 boilers)

- Harris County, TX (123 boilers)

- Milwaukee County, WI (122 boilers)

- Los Angeles County, CA (111 boilers)

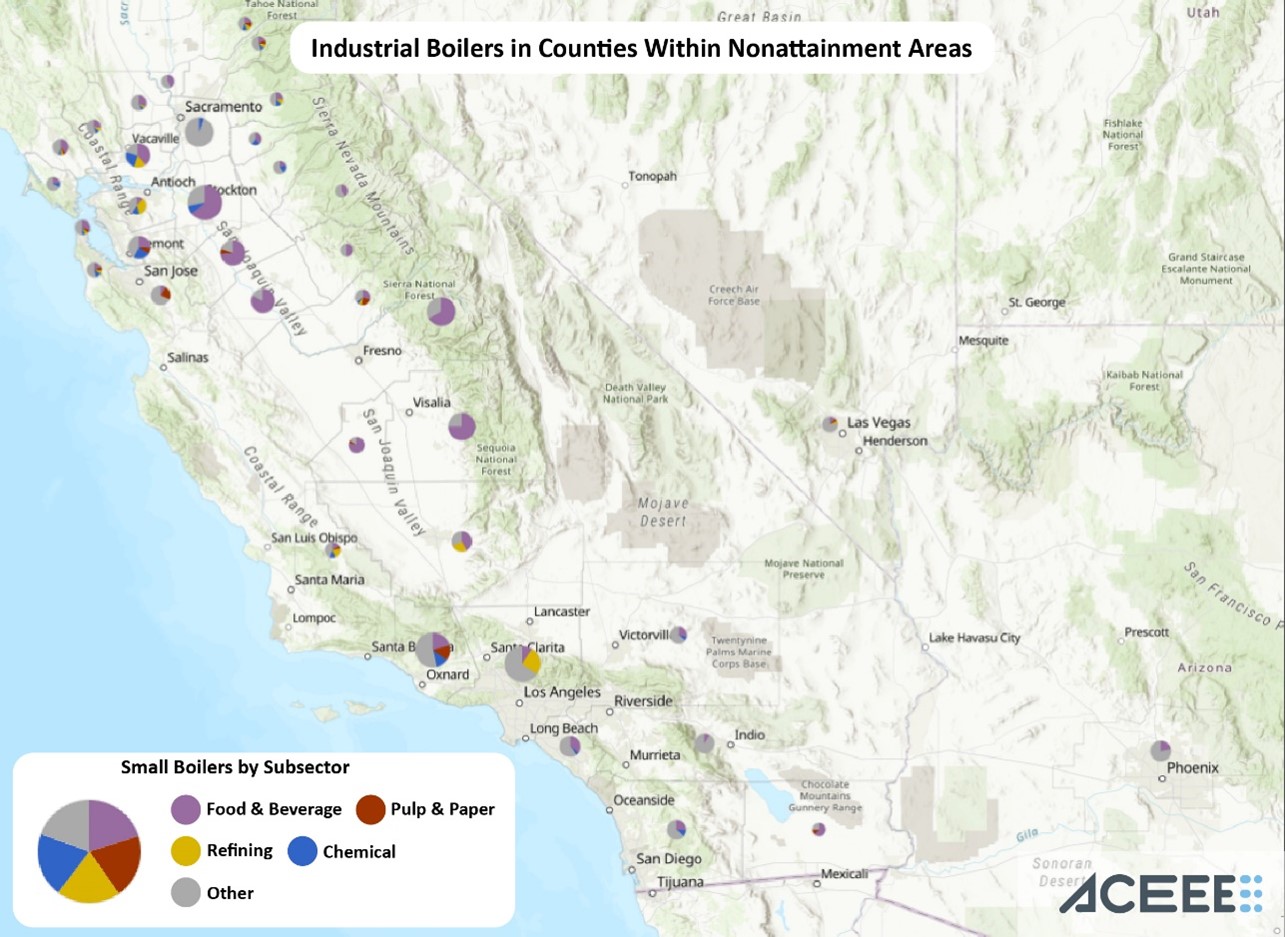

Count of small industrial boilers (≤50 MMBtu/hr) in counties within ozone nonattainment areas (average per county is 31.4 small boilers). Many of these boilers are found in California, Texas, the Northeast, and the Midwest. (Click map image to view the full interactive map.)

Electrification opportunities vary by industrial subsector and fuel type

Some boilers, such as those used for temperature processes below 150°C, will be easier to replace with IHPs than others. For example, the share of total heating capacity that falls below 150°C is about 99% for food and beverage manufacturing, 60% for chemicals, 44% for paper, and 26% for refining. We mapped the small boilers based on subsectors with low-temperature heat needs and growing momentum for IHP installations.

In almost 40% of the counties mapped, these target subsectors make up the majority of boiler applications.

Small boilers are distributed across different industrial subsectors in different regions of the country. For example, small boilers used in food and beverage manufacturing dominate in California (shown in image) while the chemicals subsector makes up large shares across other regions, especially the mid-Atlantic and Northeast (click image to view full interactive map).

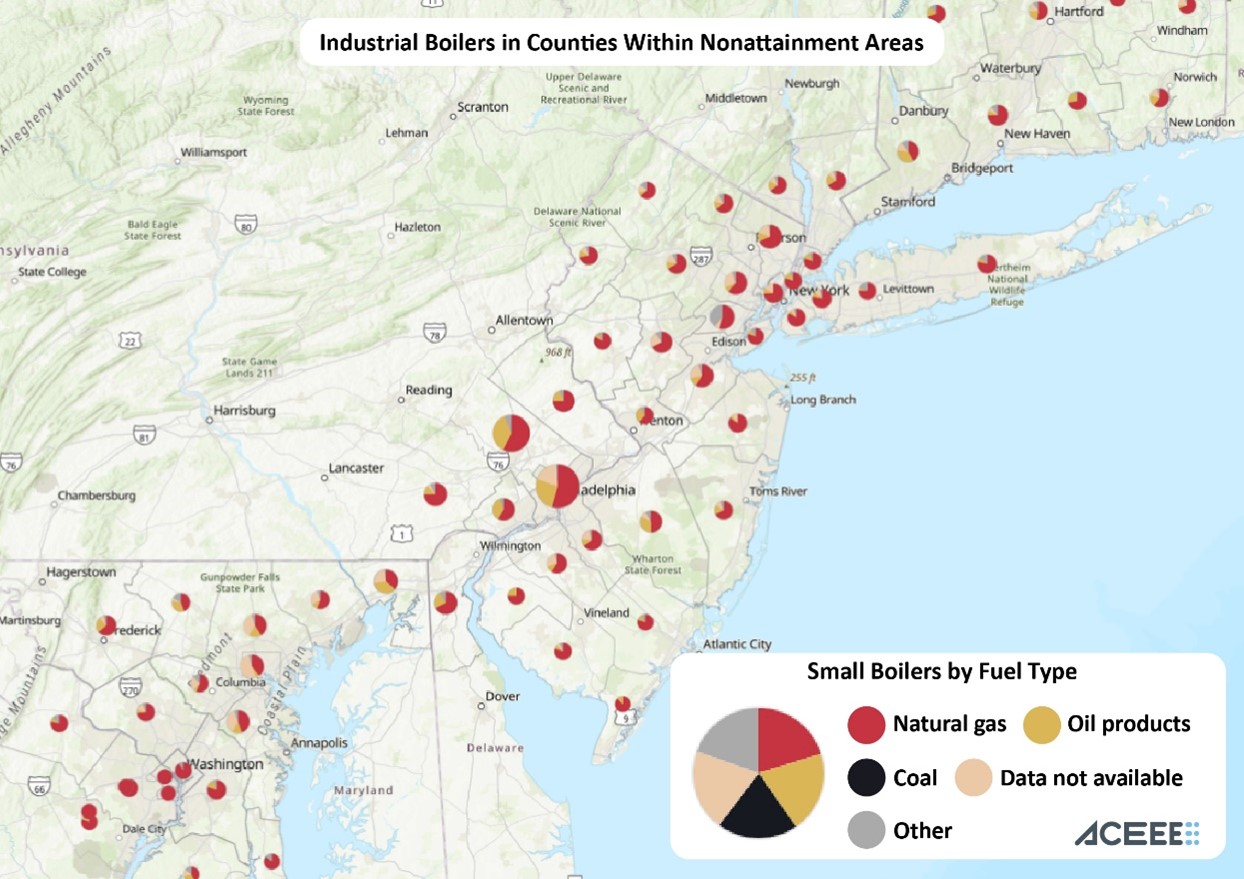

Additionally, we mapped the fuel mix of the boilers in the counties of focus. Counties with a large number of boilers, regardless of their fuel source, would benefit from IHPs, but coal-fired and oil-fired boilers are the most urgent to electrify. Coal-fired boilers emit two to four times more nitrogen oxides (NOx) than gas boilers, which are the most common type and the least polluting. NOx can cause asthma, cancer, and heart problems and contribute to ozone formation. While the best pollution-control technologies can reduce NOx emissions by 50–80%, electrification via IHPs completely eliminates NOx and other forms of point-source pollution, such as particulate matter.

Some regions have small industrial boilers that burn more-polluting fuels, such as oil and coal. While the vast majority of boilers across the nation are natural gas boilers, the Northeast has many oil-product boilers. (Click map image to view the full interactive map.)

Counties can help speed the transition to non-polluting technology

County and regional officials can use the map to support better health for residents, with a focus on sectors and fuel mixes where IHPs are immediately applicable and can have the most significant impact. For example, the South Coast Air Quality Management District (SCAQMD), which covers four counties in Southern California, portions of which are in extreme nonattainment, recently decided to use its authority to limit heating equipment of 2 MMBtu/hr or less, including boilers, to zero NOx and carbon monoxide emissions. SCAQMD plans to expand this rule to larger equipment in the coming years.

States can also use incentive programs to improve air quality while supporting the adoption of cleaner technologies. For example, a $25-million Clean Air Program grant program offsets the direct costs of purchasing industrial air pollutant emission reduction equipment in Colorado. Pennsylvania has just initiated an almost-$400-million industrial decarbonization program that prioritizes projects that can demonstrate local benefits, such as reducing co-pollutants, in addition to carbon emission reductions.

Public awareness efforts, such as local air pollution awareness programs in Illinois, could also help spur the adoption of IHPs and other non-polluting industrial technologies. Local leaders can help their communities engage directly with local industry and electricity utilities to advocate for more electrification pathways that improve health.

The counties highlighted in our map should push for progress today to meet air quality regulations, deliver benefits to their community, and support a more efficient, modernized manufacturing sector.